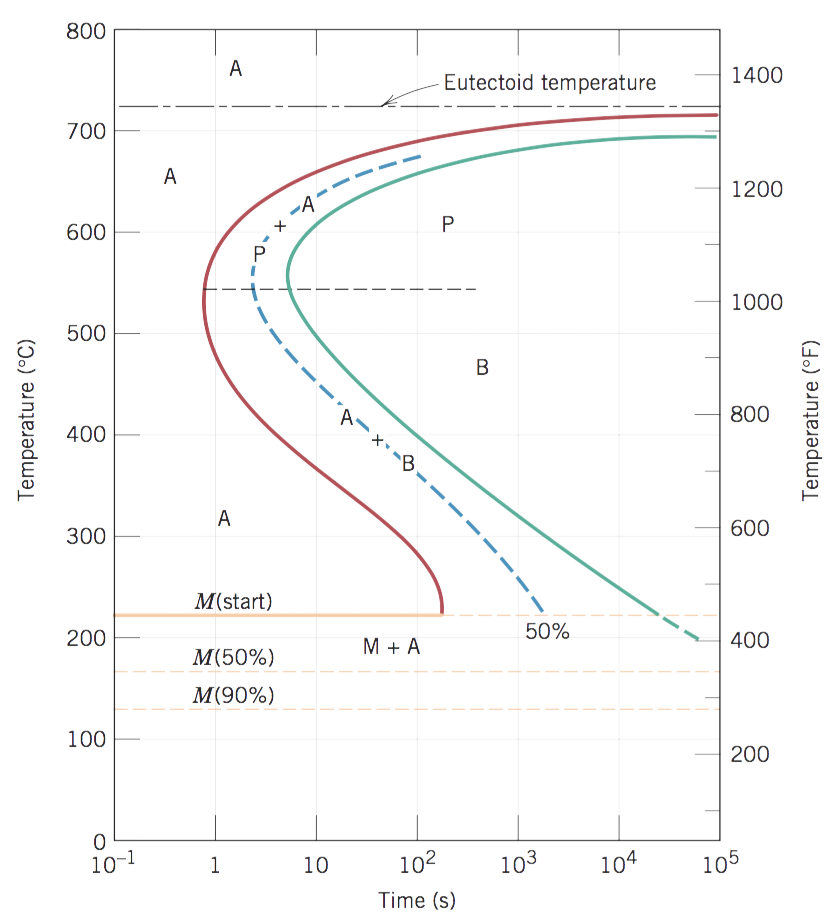

Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments. In each case assume that the specimen begins at 760\(^\circ\)C and that it has been held at this temperature long enough to have achieved a complete and homogeneous austenitic structure.

Figure 10.22

- (a) Cool rapidly to 700\(^\circ\)C, hold for 10\(^4\)s, then quench to room temperature.

- (b) Reheat the specimen in part (a) to 700\(^\circ\) for 20 h.

- (c) Rapidly cool to 600\(^\circ\)C, hold for 4 s, rapidly cool to 450\(^\circ\)C, hold for 10 s, then quench to room temperature.

- (d) Cool rapidly to 400\(^\circ\)C, hold for 2 s, then quench to room temperature.

- (e) Cool rapidly to 400\(^\circ\)C, hold for 20 s, then quench to room temperature.

- (f) Cool rapidly to 400\(^\circ\)C, hold for 200 s, then quench to room temperature.

- (g) Rapidly cool to 575\(^\circ\)C, hold for 20 s, rapidly cool to 350\(^\circ\)C, hold for 100 s, then quench to room temperature.

- (h) Rapidly cool to 250\(^\circ\)C, hold for 100 s, then quench to room temperature in water. Reheat to 315\(^\circ\)C for 1 h and slowly cool to room temperature.